Virtually all of our clients are always looking to save money. Due to the ever-present inflation (the rate may vary but it is always there), the prices of raw materials and commercial components are always inching up, cutting the profitability of their products. Often, it is not possible for them to raise their prices. The only alternative is to lower costs.

Sometimes, the “obvious” solutions like reducing the gauge of metal parts or using a lower cost material are not viable alternatives – those “solutions” having already been implemented earlier. Where else can you look?

An example of such a situation occurred in the mid-1970s when a company had done all of the obvious things but still needed to reduce their costs. All of the metal parts were being stamped, the painting line was conveyorized and all fasteners were standard commercial parts. The material that went into making the porcelain (ceramic) part was literally “dirt cheap” so there were no savings to be had there. Or were there?

Upon initial investigation, it was discovered that the reason the price of this ceramic part kept increasing was because of the increase in the cost of the fuel used to heat the kilns that cured the part. The part had to be “fired” until it was cured; there was no getting around that. Then it was discovered that, everything else being equal, curing time was directly related to wall thickness. This opened the door to a viable solution.

After a very quick study of the ins and outs of the actual process of grinding the ingredients, making the slurry, pressing the parts, drying and then firing them, a redesign of the part was done. The revised part weighed 30% less than the original, but had more uniform, and most importantly, thinner walls.

The savings in material cost were minimal. (It was dirt cheap to begin with.) However, the reduced cycle time in the kilns saved so much energy that the delivered price was significantly lower.

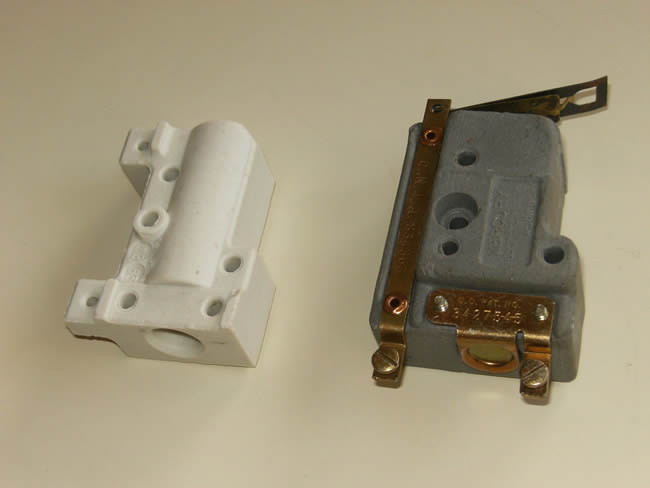

In the picture above, the original “brick” (gray ceramic) is shown with the hardware attached. On the left is the revised white ceramic part. Note how much material has been removed. It may not be obvious in the photo but the identical metal parts and assembly equipment were used in producing this revised subassembly. This resulted in a running change, with no scrap (obsolete) parts generated. They just used up the existing stock of the gray ceramics and then went right into using the white ones.

How can we help you save money?